Performance

Kynar® provides the highest performance available in an air dry coating

Fluorocarbon Polymers are recognised throughout the world as being the most stable resins known to man for providing protection against U.V. light. Its properties make it the best coating for aluminium and steel because of its resistance to the effects of weathering.

Kynar® Performance surpasses the best urethane finishes

| Kynar® ADS Restoration Film Characteristics and Properties | ||

| Film Characteristics | Ref.AAMA 2605.98 Paragraph Number and Performance Requirements | Kynar® ADS System Performance (over properly treated aluminium) |

| Colours Available | - | Standard and custom on request |

| 60° Gloss, ASTM D-523-67 | 7.2 low, medium, and high | Medium gloss (25-35) |

| Dry Film Thickness | 4.3 1.2 mils minimum (2 coats) | 0.25 ± 0.05 mil primer coat; 1.0 mil min colour coat |

| Colour Uniformity | 7.1 visually controlled | Colour instrumentally and/or visually controlled |

| Salt spray Resistance 5% Salt @ 100°F | 7.8 1/16" max. undercutting 4000 hours exposure | Meets or exceeds spec. |

| Humidity Resistance 100% RH @ 100°F | 7.8 few #8 blisters max. 4000 hours exposure | Meets or exceeds spec. |

| Resistance to Acid Pollutants | 7.7 Max. 5 E Units (NBS) Colour Change | Meets or exceeds spec. |

| Weathering - Colour Retention ASTM D-2244-68 | 7.9 Max. 5 E Units (NBS) Colour Change, 10 yrs, 45° South Florida | Excellent - exceeds spec. |

| Chalk Resistance | 7.9 Max Rating 8, 10 yrs, 45° South Florida | Excellent - exceeds spec. |

| Erosion | 7.9 Max 10% loss - 10 yrs 45° South Florida | Excellent - meets or exceeds spec. |

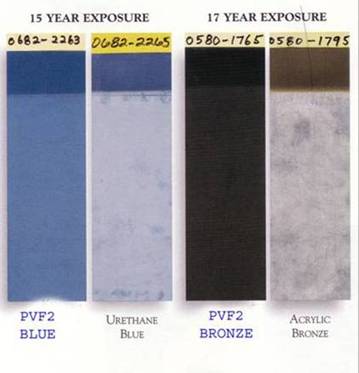

Superior chalking and weather resistance – Florida Exposure

Comparison between the performance of PVF2 and Urethane and Acrylic based paints.

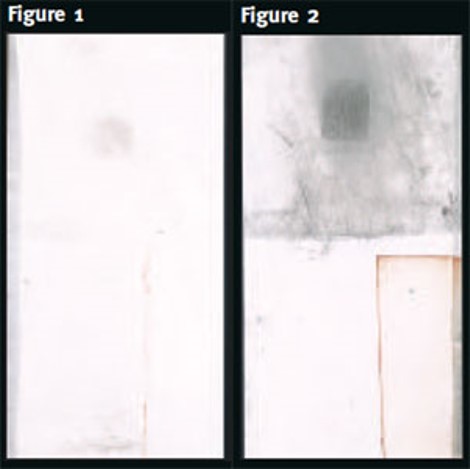

Kynar® - Excellent Dirt Shedding

Coatings based on Kynar Aquatec® emulsions pick up very little dirt, which allows white coatings to stay white. Figures 1 and 2 show the dirt shedding performance of these coatings compared to an acrylic coating.

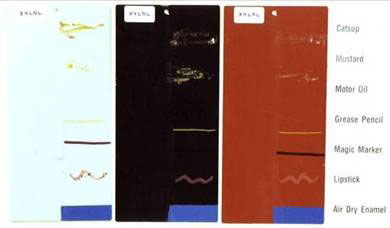

Spot and Graffiti Tests

The easy reparation of PVF2 panels even after use of motor oil, magic marker, lipstick and other substances traditionally difficult to remove or cover.

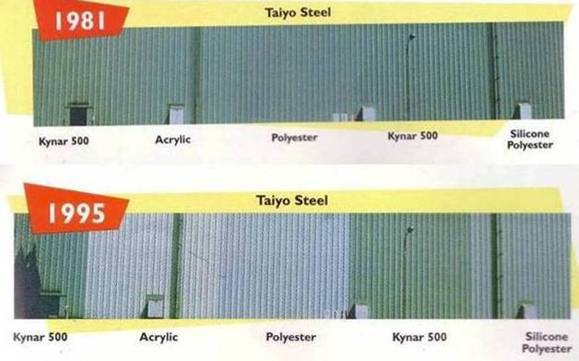

Taiyo Steel Test - Kynar 500

14 years later in 1995 you can see the difference between the performance of Kynar 500 as opposed to Acryllic and Polyester Coatings.

15 year Warranty for Coatings

THE ULTIMATE PROTECTION

American Architectural Manufactures Association "Voluntary Specification for High Performance Organic Coatings on Architectural Extrusions and Panels." Publication No. AAMA 605. 2-98